To be a built-to-last Enterprise

China

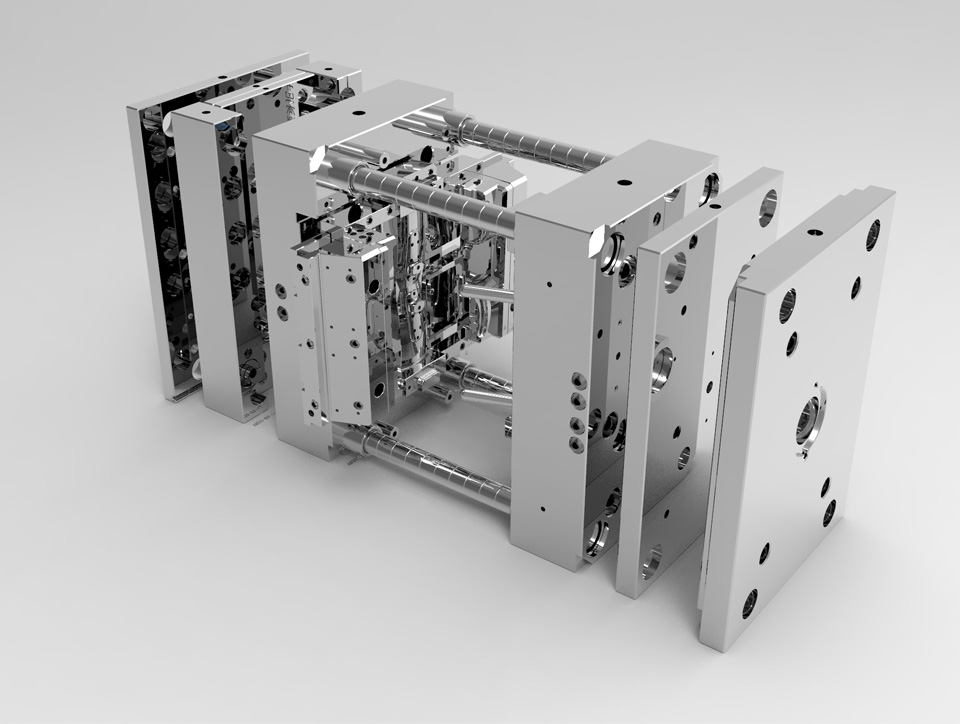

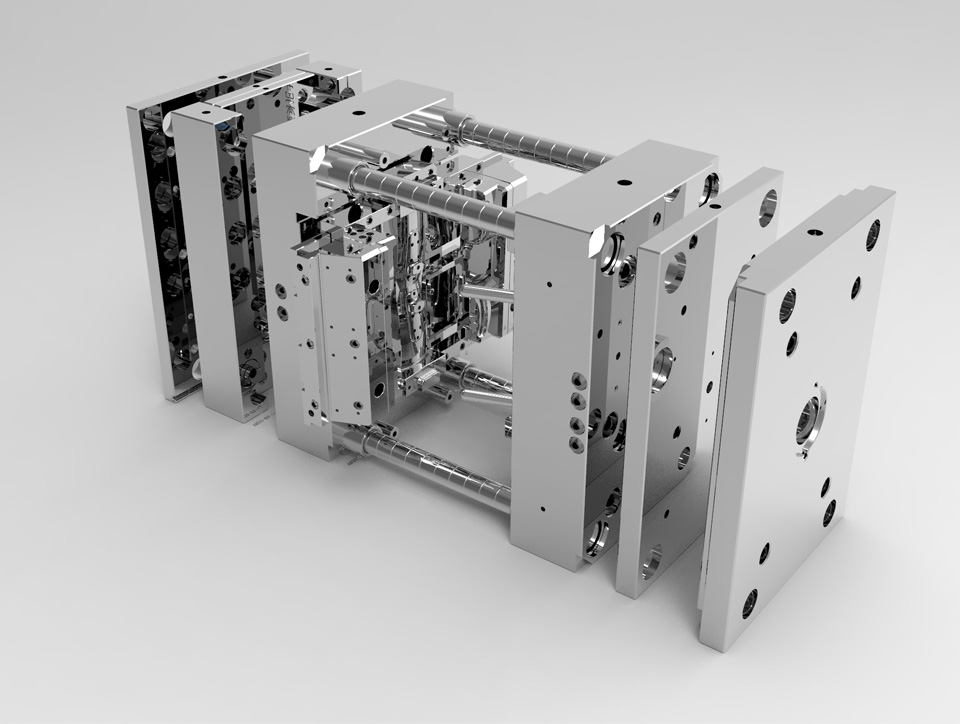

Toolmaker Mold BuildingInjection MoldingPrecision Components

One-stop Total Plastic Solution Provider .

We’re here to answer any question you may have.

HongTu Mold CO., Limited is a plastic injection mold maker and injection molding processor in China. We were founded in 1998 in HK with facilities in Bao’an District, Shenzhen City, after 20 years of development, Hongtu Mold has become a one-stop total plastic solution provider in China.

Our molds and molded parts widely apply to various industries, like Automotive, Medical and Health care, Industrial, Agricultural, Home appliance, Electronics, Smart phones, Wearable devices, Telecommunication Equipments and etc.

And as a one-stop total plastic solution provider, our service includes plastic components mechanical design, mold design, mold components machining, mold building, plastic injection molding. We believe that our value is to make our customers successful, always put our customers’ requirements the first priority, develop together with our customers, get stronger together with our customers. Focus on reasonable price, good quality, on-time-communication, and on-time-delivery, make the best for your projects!

One of the frustrating challenges centered around injection mold making is the lead time, we have been devoted to shorten the lead time by:

Customer satisfaction starts with quality, which is why we strive to exceed customer expectations with every product delivered. To achieve this goal, we have established professional inspection standards throughout the production process to guarantee that we comply with your specifications. This commitment to quality has been a cornerstone of our company’s culture since the very beginning and is carried out daily by our team.

HongTu Mold has been expanding in Automotive including Interior, Exterior, Instrument Panel and functional parts.

HongTu Mold understands that companies in Medical and Healthcare market demand a strong and efficient product development partner.

HongTu Mold offers complete tooling, mold making, and plastic injection molding of high precision parts for electronics industry.

HongTu Mold offers competitive price for injection molds and molded parts for Industrial market.

HongTu Mold provides mold making and injection molding services to a wide variety of appliance product companies, whether you’re looking for a solution for a simple or sophisticated component, we can add value to your product.

HongTu Mold has the expertise, equipment and experience to manufacture molds and plastic parts and components for communication device. Contact us now to find out more.

HongTu Mold uses our top of the line machinery and manufacturing technology to create high-quality molds for Agricultural industry. The molds meet their exact requirements and exceed expectations in terms of their functionality.

Please provide the following data when requesting for quotation, and we will offer a reasonable quotation to you within 3 days.

― Learn more

A variety of factors directly effect tool up time, Increased tool life, Shortened delivery cycles, better quality parts, and focused

― Learn more

Manufacturing companies run on the margins. Controlling costs is a bottom line outcome,

― Learn more

Treating your tools and outsourced machining as investments has a positive impact, on your team, your equipment and your bottom line

― Learn more

Adding {{itemName}} to cart

Added {{itemName}} to cart